How To Test Engine Cylinder Compression

The process of testing engine cylinder compression is a crucial diagnostic tool used to assess the overall health and performance of an internal combustion engine. Compression testing can help identify issues such as worn piston rings, damaged cylinder walls, or blown head gaskets, which can lead to decreased engine power, reduced fuel efficiency, and potentially even engine failure. In this article, we will delve into the step-by-step process of how to test engine cylinder compression, discuss the importance of compression in engine performance, and explore the various tools and techniques used in the process.

Understanding Engine Compression

Engine compression refers to the pressure that builds up inside the engine’s cylinders during the compression stroke. This pressure is a result of the piston moving upwards, compressing the air-fuel mixture in the cylinder, which is then ignited by the spark plug, producing power. The compression ratio, which is the ratio of the cylinder’s volume when the piston is at the bottom of its stroke to the volume when the piston is at the top, plays a significant role in determining the engine’s overall performance and efficiency. A higher compression ratio can lead to increased power output, but it also requires higher-octane fuel to prevent engine knocking or pinging.

The compression test is a diagnostic procedure used to measure the compression pressure in each cylinder, helping to identify any potential issues that may be affecting engine performance. By comparing the compression readings from each cylinder, technicians can determine if there are any significant variations, which can indicate problems such as leaks, blockages, or mechanical issues.

Tools and Equipment Needed

To perform a compression test, you will need a few specialized tools and equipment, including a compression gauge, which is a device that measures the pressure inside the cylinder. There are two types of compression gauges: mechanical and digital. Mechanical gauges are more common and provide a precise measurement of the compression pressure, while digital gauges offer a more convenient and easier-to-read display. Additionally, you will need a spark plug socket to remove the spark plugs, and a throttle valve holder to keep the throttle valve open during the test.

| Tool | Description |

|---|---|

| Compression Gauge | Measures the pressure inside the cylinder |

| Spark Plug Socket | Removes the spark plugs |

| Throttle Valve Holder | Keeps the throttle valve open during the test |

Step-by-Step Compression Test Procedure

The compression test procedure involves several steps, which must be followed carefully to ensure accurate results. The first step is to warm up the engine to its normal operating temperature. This is essential, as a cold engine can produce inaccurate compression readings. Next, remove the spark plugs from each cylinder, using a spark plug socket. This will allow the compression gauge to be inserted into the spark plug hole.

Once the spark plugs are removed, install the compression gauge into the spark plug hole, making sure it is securely seated. Then, open the throttle valve and hold it open using a throttle valve holder. This will allow the engine to draw in air and create a vacuum, which is necessary for the compression test. Finally, crank the engine several times to build up compression, and take a reading from the compression gauge.

Interpreting Compression Test Results

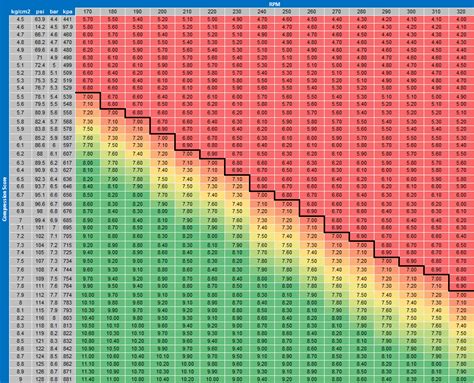

The compression test results can provide valuable insights into the engine’s condition. A healthy engine should have compression readings that are within 10% of each other. If the readings are significantly lower in one or more cylinders, it can indicate a problem such as a leaky head gasket, cracked cylinder head, or worn piston rings. On the other hand, if the readings are consistently high across all cylinders, it can indicate a problem such as a clogged air filter or faulty fuel injectors.

It is essential to compare the compression readings from each cylinder to determine if there are any significant variations. A difference of more than 10% between cylinders can indicate a problem that requires further investigation. Additionally, looking for patterns in the compression readings can help identify specific issues, such as a leaky head gasket or a cracked cylinder head.

- Healthy engine: Compression readings within 10% of each other

- Low compression: Leaky head gasket, cracked cylinder head, or worn piston rings

- High compression: Clogged air filter or faulty fuel injectors

Technical Specifications and Performance Analysis

The technical specifications of the engine, such as the compression ratio, displacement, and power output, can significantly impact the compression test results. For example, a high-performance engine with a high compression ratio may require a more precise compression gauge to accurately measure the compression pressure. Additionally, the engine’s condition, such as the age, mileage, and maintenance history, can also affect the compression test results.

A performance analysis of the engine can provide valuable insights into its overall health and performance. This can include analyzing the engine’s power output, fuel efficiency, and emissions to determine if there are any issues that require attention. By combining the compression test results with a performance analysis, technicians can gain a more comprehensive understanding of the engine’s condition and make informed decisions about any necessary repairs or maintenance.

| Specification | Description |

|---|---|

| Compression Ratio | Affects the engine's power output and efficiency |

| Displacement | Affects the engine's power output and torque |

| Power Output | Affects the engine's performance and fuel efficiency |

Future Implications and Real-World Applications

The compression test is an essential diagnostic tool that has numerous real-world applications. In the automotive industry, compression testing is used to diagnose and repair engine problems, ensuring that vehicles are running efficiently and safely. In the marine industry, compression testing is used to diagnose and repair engine problems in boats and other watercraft. Additionally, compression testing is used in the aviation industry to diagnose and repair engine problems in aircraft.

In the future, compression testing is likely to become even more sophisticated, with the development of new technologies and tools. For example, wireless compression gauges are being developed, which can provide more accurate and convenient readings. Additionally, data analytics is being used to analyze compression test results and provide more detailed insights into engine performance and health.

What is the purpose of a compression test?

+The purpose of a compression test is to diagnose engine problems, such as low compression, by measuring the pressure inside the engine’s cylinders.

What tools and equipment are needed to perform a compression test?

+To perform a compression test, you will need a compression gauge, spark plug socket, and throttle valve holder.

How do I interpret the results of a compression test?

+The results of a compression test can provide valuable insights into the engine’s condition. A healthy engine should have compression readings that are within 10% of each other. If the readings are significantly lower in one or more cylinders, it can indicate a problem such as a leaky head gasket, cracked cylinder head, or worn piston rings.